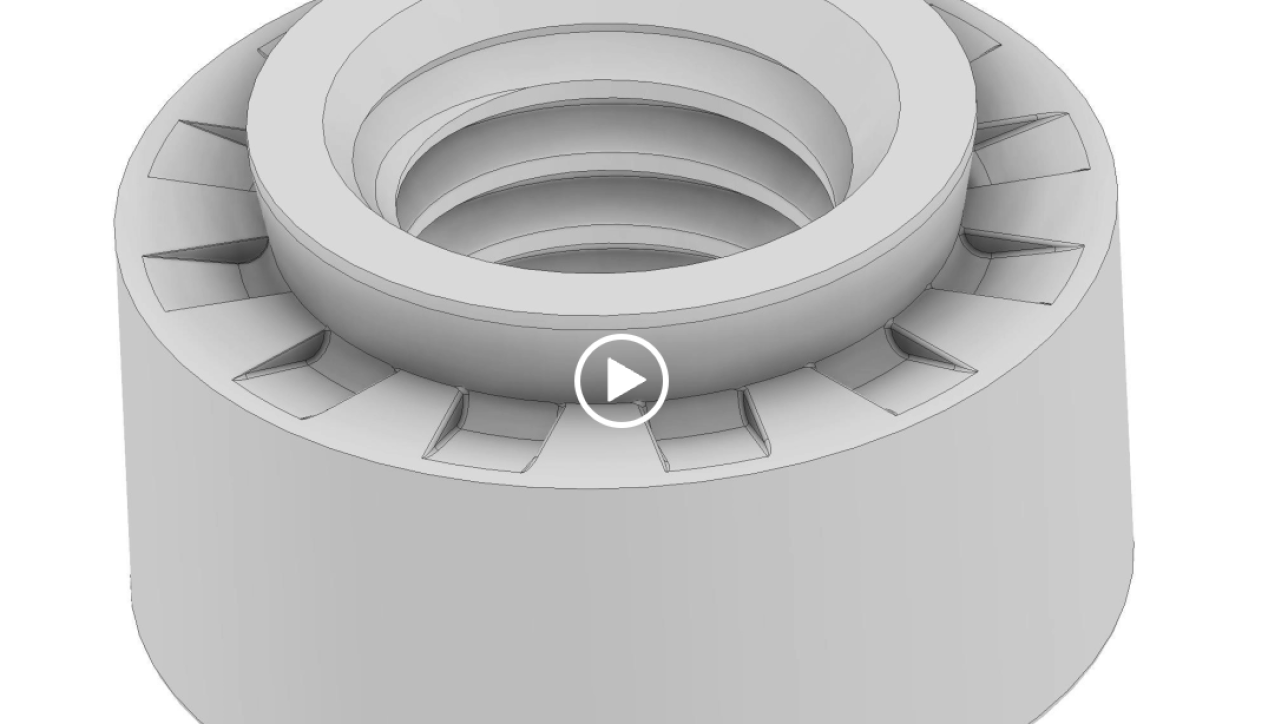

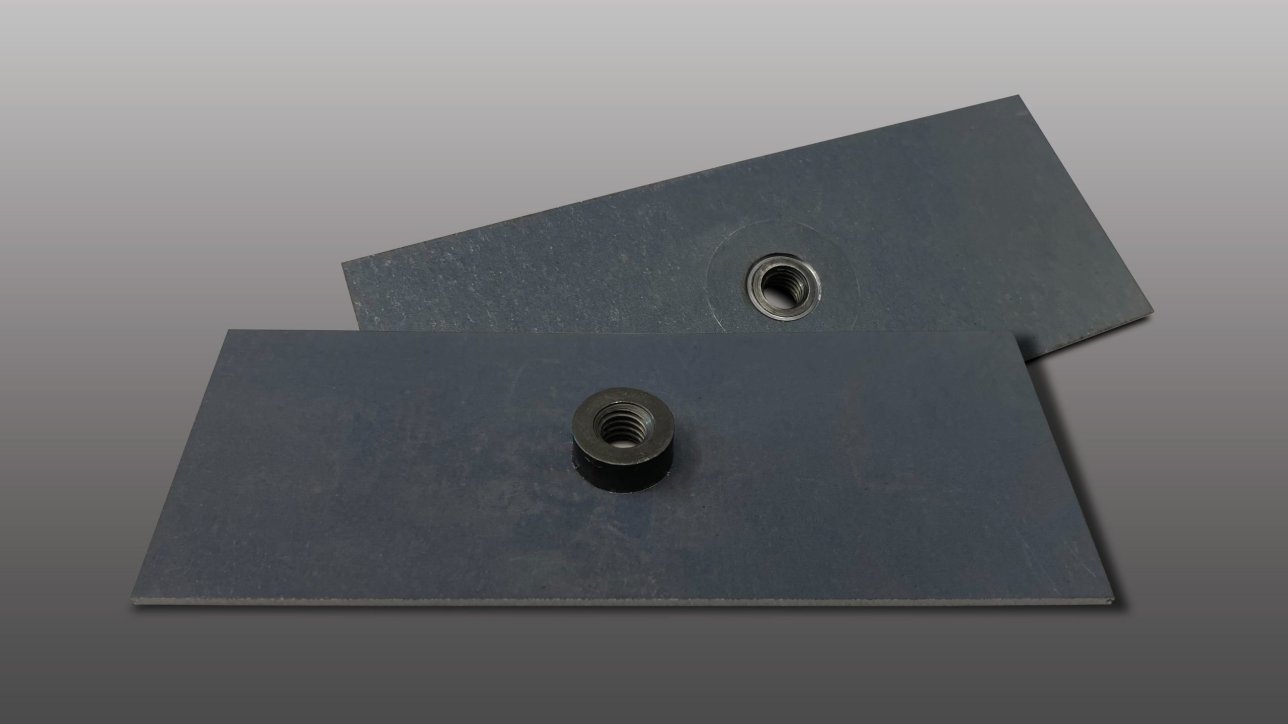

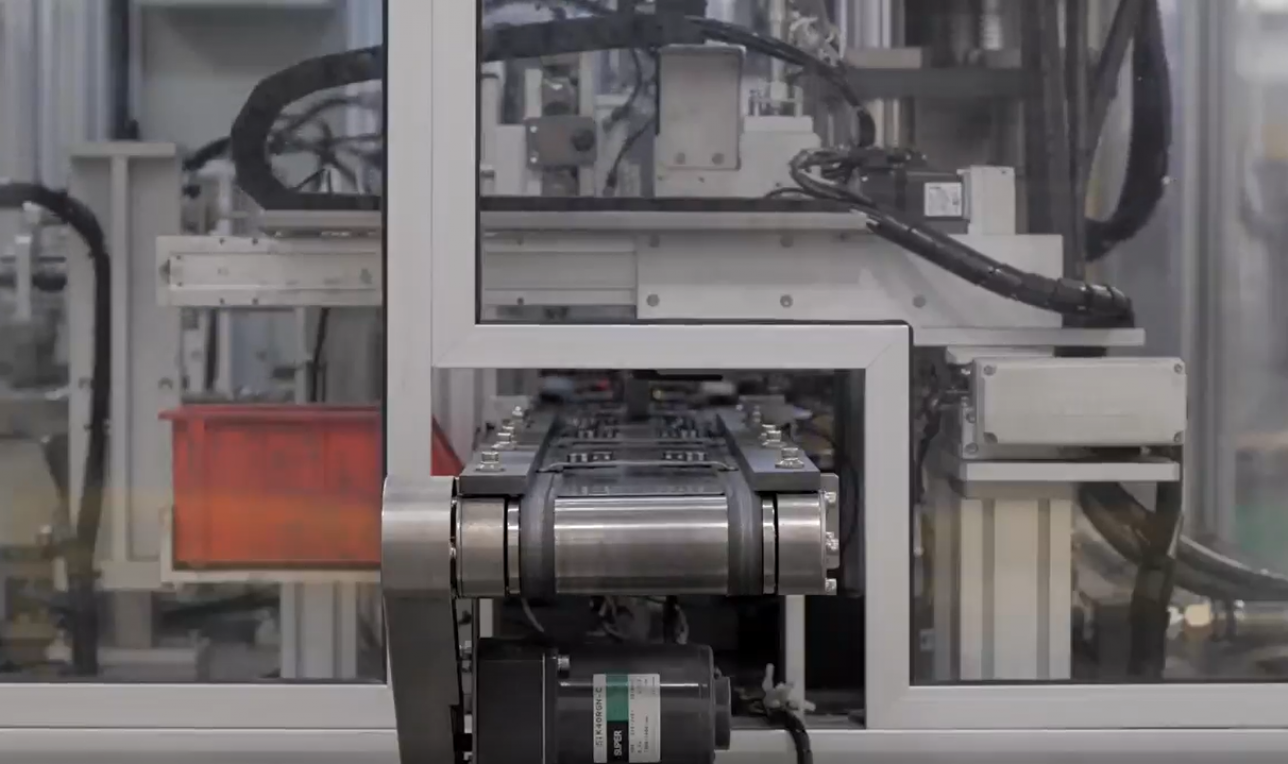

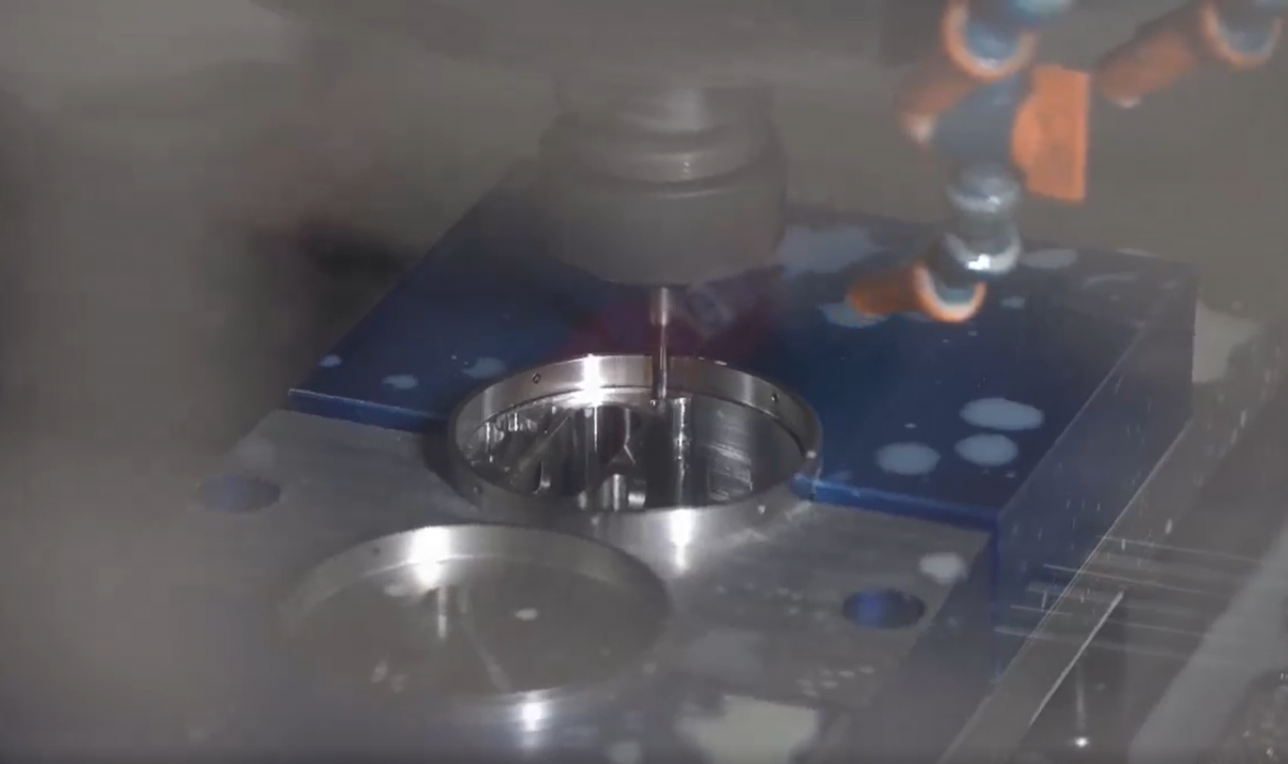

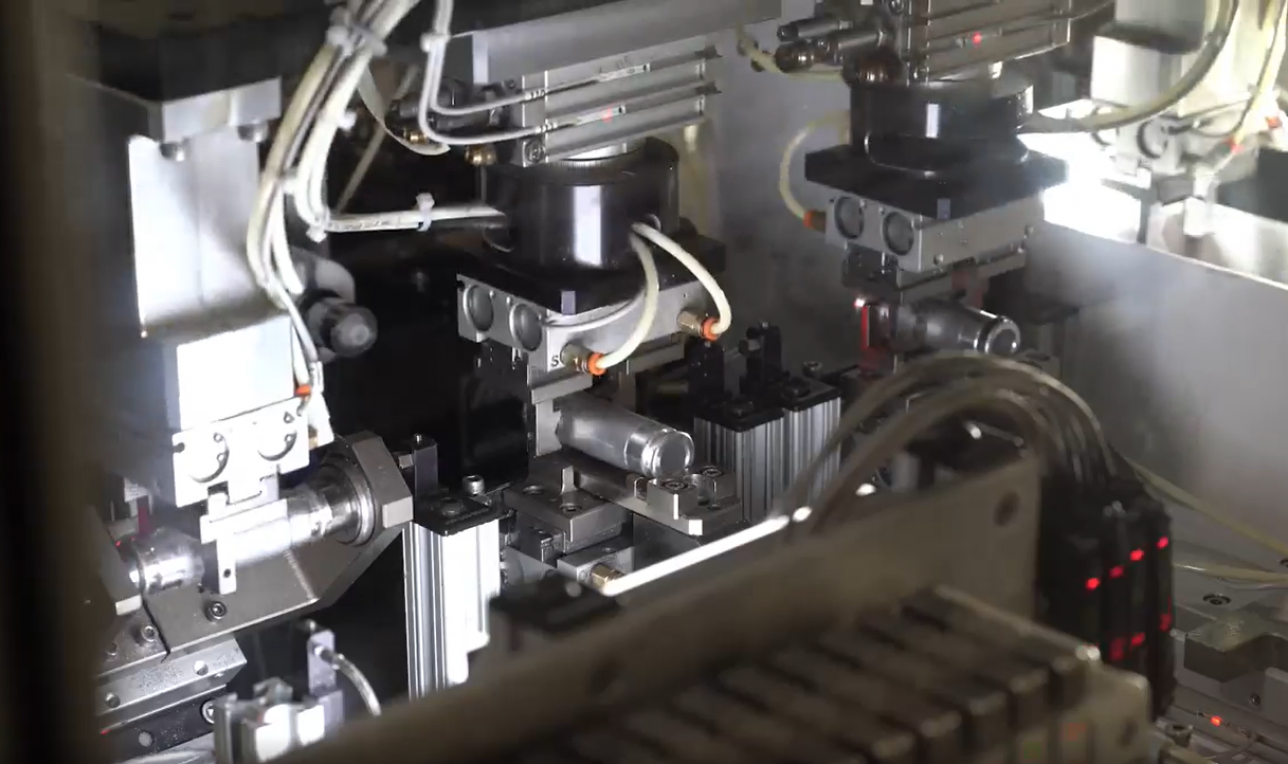

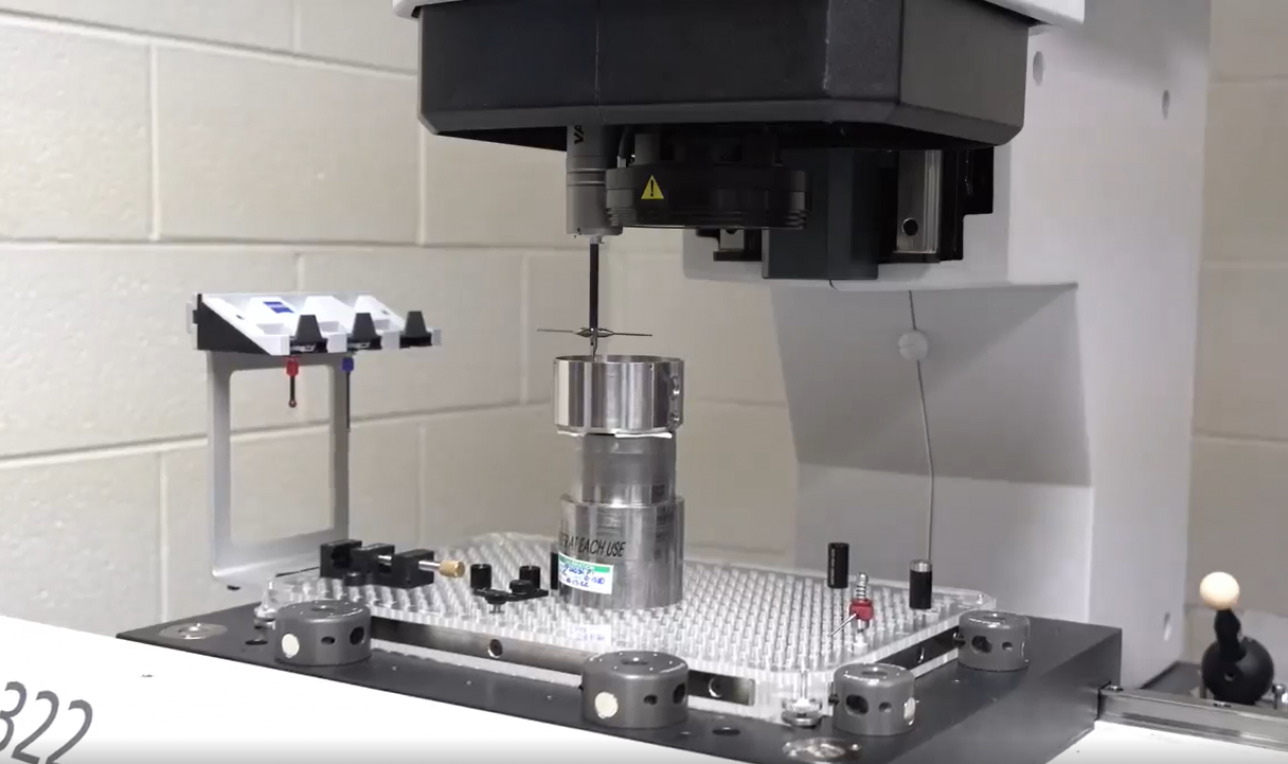

In partnership with Utica International Inc., Ramco has developed the Ultra Pierce Nut for use with Utica International Inc.’s Thermal Integrated Pierce / Clinch Nut Installation Method to install pierce and clinch fasteners to ultra-high-strength steels.

The lightweight and high strength combination of the Ultra Pierce Nut with the thermal integrated method makes it an ideal way to install fasteners in automotive body in white structural components such as A pillars, B pillars, C pillars, seats and side door reinforcements, etc.

The pierce and clinch nuts are available as threaded or non-threaded for applications that require self-threaded bolts. Thread size ranges between M5 and M12 with a suggested metal application thickness of 0.7 mm-2.0 mm. The fasteners meet ISO 898-2 Property Class 10 requirements.

Are you ready to talk about your next project? Ask us how we can help with your engineering challenge and customize a solution.