We are thankful every day for the hard work our employees put into keeping Ramco a safe and top-notch manufacturer. Happy Thanksgiving to our staff and their families, our customers, and all of our friends and associates!

We are thankful every day for the hard work our employees put into keeping Ramco a safe and top-notch manufacturer. Happy Thanksgiving to our staff and their families, our customers, and all of our friends and associates!

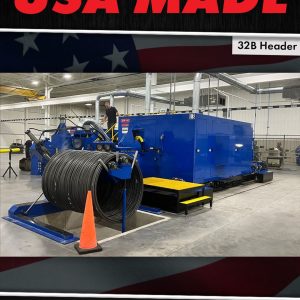

Ramco Ohio now has two new 32B nut formers. These will produce much-needed internally threaded fasteners, primarily for automotive applications. Ramco has now added four new headers to its floor in 2023.

The 32B nut former focuses on standard large nuts, from M14 to M20. Additional specs:

🇺🇲 M14-M20 nuts

🇺🇲 Weld nuts, locknuts, nylon insert nuts, specialty nuts

🇺🇲 6 Station 440 ton forging load

🇺🇲 Max cutoff 32MM

🇺🇲 20,000,000 parts per year per machine

Start the conversation and keep your supply chain consistent. https://lnkd.in/gBEGMiHF

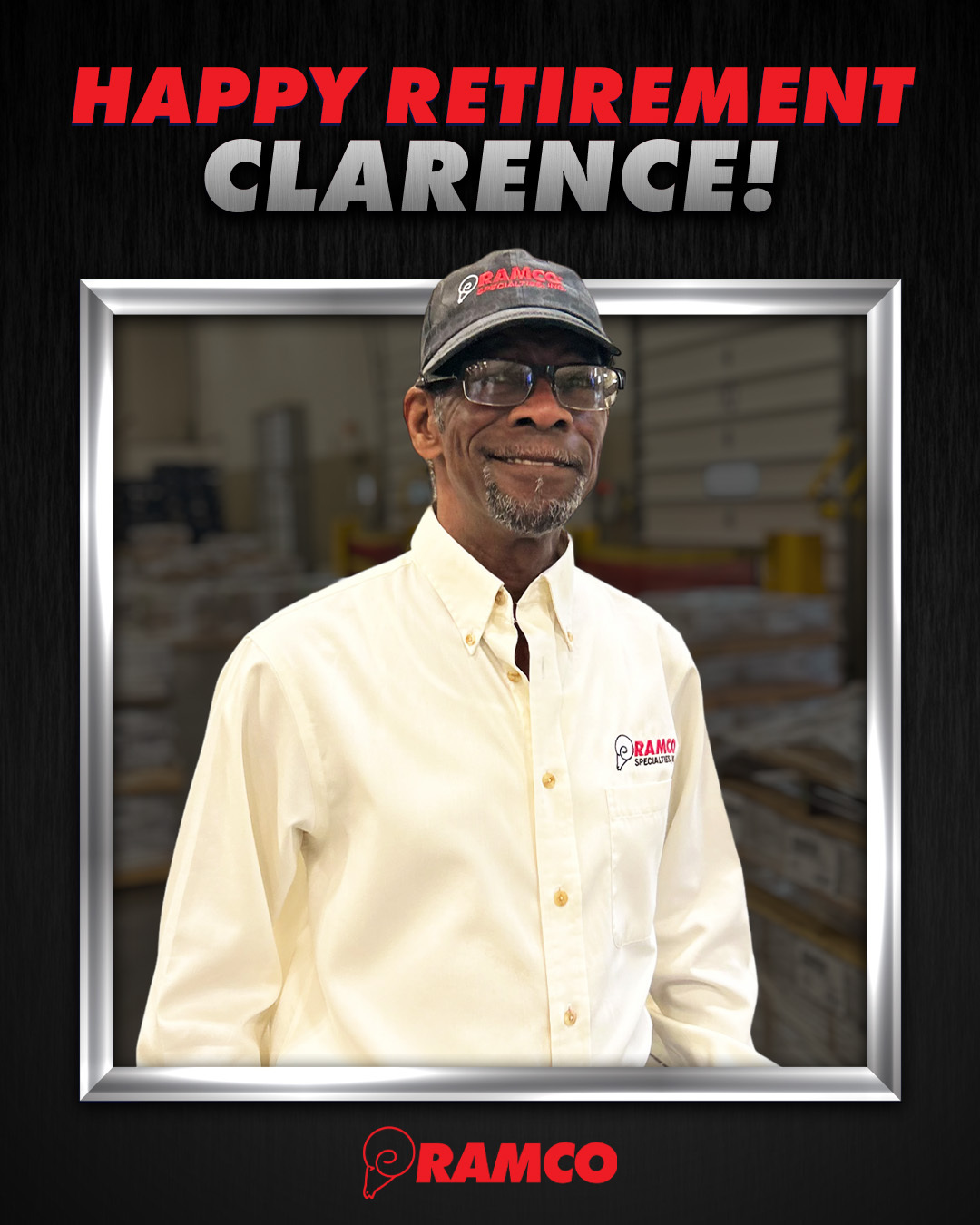

We would like to congratulate Clarence Mcintyre on his retirement!

We would like to congratulate Clarence Mcintyre on his retirement!

Clarence has been a valued member of the Ramco team for the last 13 years. He has been a staple on the shipping dock, and his enthusiasm, knowledge and expertise in shipping have been part of Ramco’s culture throughout his career.

We have always been confident, regardless of what was thrown his way, that every truck would be properly loaded and to the customer on time. We are excited to see Clarence reach this new milestone and are thankful for the years of dedicated service he provided.

Clarence plans to spend time working on projects around the house in his retirement.

Looking for a domestic manufacturer of large diameter internally threaded fasteners? Ramco’s newest 32B header can produce larger parts:

– Locknuts, Weld Nuts, Nylon Insert Nuts and Specialty Nuts

– Sizes: M18 – M24 nuts

– Automotive quality to your specifications

– Made in the USA in Hudson, Ohio

Contact our Product Development Specialists today at RamcoSpecialties.com.

O ur second Porta is now ready in Michigan!

ur second Porta is now ready in Michigan!

This machine will produce machined castings, primarily suited to meet high standards for the automotive OEM market. This includes assemblies for performance-critical applications, including electric vehicles, powertrain and chassis.

The Porta will be a part of a fully automated line from raw material to packaging.

Question: What does it take to deliver and install a 400,000 lb. header?

Answer: A lot of patience.

One of our favorite trucks just delivered this new header to our headquarters in Ohio. It takes a strong rig and an entire day to get the machine in the building and safely onto the plant floor for installation.

We also love the fact that Ramco manufactured parts that went into the truck that helped with this delivery. That’s what we call a full-circle project!

This is all a part of our commitment to easing the US supply chain crisis for our customers.

Our first Porta is now up and running in Ramco’s new Michigan location!

As part of a fully automated line, this cutting-edge equipment will produce machined castings and enable us to meet the high standards of the automotive OEM market. This investment is another step in Ramco’s dedication to improving supply chain reliability and US manufacturing.

This Porta is ready to produce parts and assemblies for performance-critical applications, including electric vehicles, powertrain and chassis.

Ramco is proud to announce that we’re expanding our Michigan operations into a new facility in New Hudson.

Ramco is proud to announce that we’re expanding our Michigan operations into a new facility in New Hudson.

With approximately 50,000 square feet of space, this move will help us pick up efficiencies by combining three buildings into one. This is an important step towards our ongoing efforts to improve our operations, streamline our processes, and better serve our customers. It will also be a welcome transition for our employees, who will get to work in a newer facility with expanded meeting, office and research spaces.

Our new Michigan facility will continue to serve as Ramco’s home for machining expertise. Ready to contact us for your next machining project?

Ramco’s latest plant expansion is now complete. Our 50,000 square-foot addition will double our cold forming manufacturing space. Our equipment is expanding to 14 cold forming machines that can produce specialty parts from M12 to M50 in diameter.

Ramco’s latest plant expansion is now complete. Our 50,000 square-foot addition will double our cold forming manufacturing space. Our equipment is expanding to 14 cold forming machines that can produce specialty parts from M12 to M50 in diameter.

We are excited about bringing manufacturing jobs back to the US. Our mission is to manufacture and distribute highly engineered metal components and fasteners to help North American Manufacturers localize their supply chain.

We recently received two new parts formers, which will help us get more domestically produced items to our customers quickly. Key stats:

We recently received two new parts formers, which will help us get more domestically produced items to our customers quickly. Key stats:

𝟭𝟵𝗕 𝗦𝗜𝗫-𝗦𝗧𝗔𝗧𝗜𝗢𝗡 𝗣𝗔𝗥𝗧𝗦 𝗙𝗢𝗥𝗠𝗘𝗥

· 175-ton forging load, 6 stations

· Can produce 35,000,000 parts per year

· Weight: 58,000 lbs

𝟮𝟬𝟲 𝗦𝗜𝗫-𝗦𝗧𝗔𝗧𝗜𝗢𝗡 𝗣𝗔𝗥𝗧𝗦 𝗙𝗢𝗥𝗠𝗘𝗥

· 390-ton forging load, 6 stations

· Can produce 14,000,000 parts per year

· Weight: 176,000 lbs

Connect with us to talk about how we can help on your part needs.